|

|

A blade with tip-speed ratio call TSR of 5 will spin at 50mph in a 10mph wind, creating its own apparent wind of ~51 mph. The apparent direction of that wind moves closer to the blade's rotational plane the faster it spins; likewise, the blade tip sees a faster and shallower apparent wind than the blade root.

As the apparent wind contacts the leading edge, it splits. Some air goes along the convex back, some goes along the concave front. The streams adhere to the blade surface and adjacent air by boundary layer effect.

The concave side air slows down, generating a net positive air pressure; the air flowing over the convex back of the blade speeds up, creating a net (and stronger) negative air pressure. Both sets of pressures act perpendicular to the surface of the blade. The forces act in all different directions and intensities, but the net force is a flexing and forward one. The flex force is canceled by the blade's stiffness; what's left is a forward vector of surprising strength:

There's a fairly narrow window of apparent wind direction or attack angle - in which a lifting airfoil will operate efficiently. The flow along its sides must be smooth, and it must remain attached to the blade surface. If it detaches, the result is lost lift, terrible drag, and turbulence, with attendant noise and vibration. These conditions are known as stalling (attack angle too steep) and luffing (attack angle too shallow.)

Wind turbine designers have developed numerous strategies to keep the apparent wind angle correct, which is especially hard given that different parts of the blade are moving different speeds, and to keep lift strong and constant along the full length of the foil. These strategies can be grouped in pairs: Taper and draft, twist and pitch. Near the hub of a propeller-style-turbine, the apparent wind is slower and closer in direction to the true wind, the blade root has a wide chord (breadth) and a fairly deep draft, and it faces more toward the true wind. The blade tip is traveling very fast, too much breadth or 'cup' would create crippling drag, so the blade there tends to be narrower and flatter. The tip also experiences an apparent wind nearly in line with its rotational plane, so it needs very little twist.

Finally, the best HAWTs (horizontal-axis wind turbines) are able to rotate the entire blade to vary TSR, optimize lift, and keep the alternator spinning at its prime electricity-making RPM. They use taper, draft, twist and pitch all at once.

For what it's worth a brief look at why the world's best engineers design HAWTs rather than VAWTs (vertical axis wind turbines). The very worst VAWTs are pure drag machines: paddles pushed by the wind. Their maximum apparent wind is the true wind MINUS their own rotational speed, so they can never go fast and the wind's force is gutted. And two-thirds of the time, a given blade is either contributing nothing or plowing headlong INTO the wind. These generally fall under the heading of Savonius Rotors. Their TSRs are always less than 1.0, and their efficiencies are gruesome.

Better, though not much, is a class of semi-lifting VAWTs classified as Darrius, Modified Darrius, or Gyro Rotors. These include the famous 'eggbeaters' and more modern designs. Almost half the time, their blades are on or near a "beam reach," moving perpendicular to the true wind, which sailors know is the fastest, most-efficient point of sail. But the back blade is operating in the wind shadow of the front one, its draft must somehow be inverted, the downwind blade is dragging some, and the upwind blade is a sea anchor. Darrius blades are pulling maybe 50% of the time. They aspire to TSRs of 2.5, they do spin faster than the wind, but not much.

THE LOW WIND

AREA MOTIVATION!

THE LOW WIND

AREA MOTIVATION!

Large 34.5" Long Blades can generate lots of

rotations in mild and dirty wind

Large 34.5" Long Blades can generate lots of

rotations in mild and dirty wind

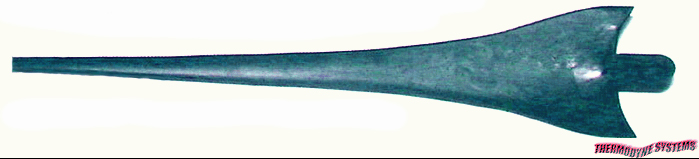

1 Carbon Fiber Wind Turbine Blade

One 28" Blade - $39.99 Plus $26.98 S&H ea.

One 28" Blade - $39.99 Plus $26.98 S&H ea.

HUB ONLY FOR HORNET 28" BLADES - HUB KIT for

5/10 BLADES -

HUB ONLY FOR HORNET 28" BLADES - HUB KIT for

5/10 BLADES -

HUB ONLY FOR HORNET 28" BLADES - HUB KIT for

11 BLADES -

HUB ONLY FOR HORNET 28" BLADES - HUB KIT for

11 BLADES -

ONE

PMA LONG SPACER

ONE

PMA LONG SPACER

ONE PMA SPACER KIT

ONE PMA SPACER KIT

|

#17MM-NBK / Special thread 17mm nut and bolt kit - $29.95 plus $9.80 For Postal Shipping. |

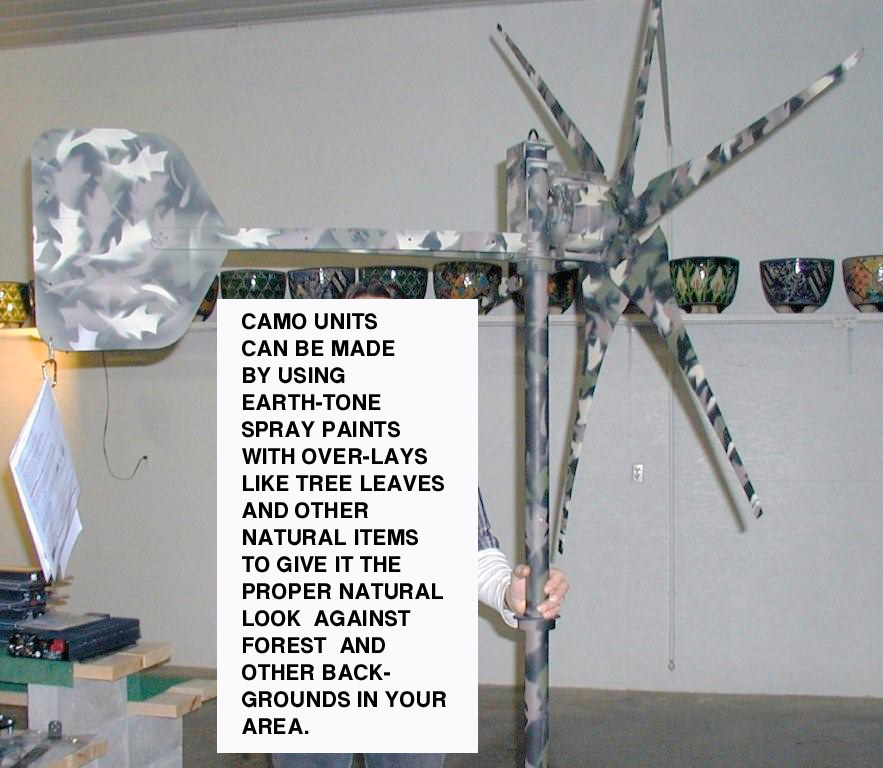

Blades can be painted to match home

or background.

Blades can be painted to match home

or background.

or - The absence of a wind turbine blade in the winds path at any given point in rotation time usually caused by over-amperage loads including connection to lower voltage batteries used in low wind speed areas or high amperage appliances or lack of blade area in the original turbine design or a mismatched PMA to blade area ratio in the design. (Way-Holes are also called 'The Unengaged Blade Area' )