Photo

shows optional fan and pulley.

Photo

shows optional fan and pulley.

![]()

![]()

If you are not sure which coil you need Email Us Here

Full

Wave Rectifier

Full

Wave Rectifier

Delco

Cases Kit

Delco

Cases Kit

Fan and pulley option -

Fan and pulley option -

TECH

NOTES:

TECH

NOTES:If it is jammed or rusted use some WD-40 on the shaft and alternately tap the mounting wings with a hammer while applying pressure to the shaft with your thumb so that the stator and it's delicate wiring harness is kept in place. NOTE: If the shaft is scored-up badly you may have to sand the shaft down to it's original 17mm size to get the front housing off.

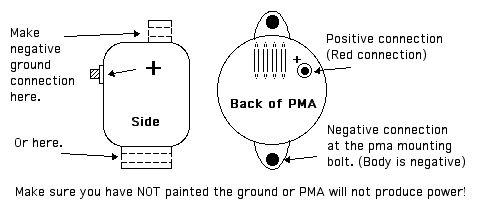

CLICK DRAWING TO ENLARGE

NO PAPER company policy. We have no written literature.

Over 175,000,000 tons of paper and other wood products are dumped into landfills annually world over.

We offer only non-polluting electronically generated information that is served here on this web site.